You use a lot of pallets to store your products in the warehouse and to ship them to customers. There are many different kinds of pallets, each of which is made to fit the needs of a different process.

There are also different kinds of pallet materials, such as wooden and plastic pallets, each of which has its own pros and cons.

In this post, I’ll tell you everything you need to know about pallets, especially plastic pallets, so you can figure out what kind of plastic pallet specifications you need for your material handling process.

But before we go any further, make sure you have also joined the scmguide telegram channel so you don’t miss new blog posts and can learn more about supply chain management.

Table of Contents

How to make pallets last longer

Wooden pallets are known to last longer than plastic ones. But if you don’t use it right, none of these benefits will come true.

How should you use plastic pallets?

Let’s see.

Choose a pallet that has the specifications you need

The first thing you need to do is figure out what your needs are so you can figure out what kind of pallet specifications you need to meet those needs.

For instance, you might want to be able to put your stack of pallets on top of another stack of pallets. In this case, you’ll need a double-deck pallet instead of a single-deck one that can’t be stacked on top of other goods.

I will talk about these kinds of pallets in the next section.

Adjust the distance between your forklift’s forks by lining up the holes on the pallet with the forklift’s forks

In your warehouse, you will move pallets with a forklift or a hand pallet truck. As you do this, make sure the distance between your tool’s forks matches the distance between the fork holes on the pallet. This will keep your plastic pallets safe and also keep them from getting broken.

Do not move pallets by pushing them with the forks of a forklift

Pallets aren’t meant to be moved by pushing or pulling. So, don’t push pallets. Instead, move them with forklift forks or hand pallet trucks. You only have to lift it (according to how the pallet is designed).

When lifting the pallet, make sure the forklift’s fork is fully in

Forklift forks that don’t go all the way through the pallet when lifting it will damage the top of the pallet. So, make sure the forklift fork is fully in when you lift the pallet.

Don’t throw heavy loads on pallets

Pallets are made to hold heavy loads, but not the kinds of loads that are thrown on them. Put the load on the pallet slowly, as needed, to keep it from getting damaged.

Do not throw or drop pallets from a height

If you throw or drop a pallet from a high place, it will break. Do it the right way if you want to move your pallets to a lower place. No, you can’t throw it.

Do not move a pallet by pushing it with another pallet

Avoid pushing pallets with other pallets and with the forks of a forklift. I already said that pallets are not made to be pulled or pushed across the floor. So, if you want your pallets to last, you shouldn’t do that.

Match the width of the pallet to the width of the shelf

If you store things on shelves, make sure that the width of your pallet rack is the same as the width of your pallet. Leave at least 5–10 cm of space between them for safety.

You might also like:

- 6 Effective Stocktaking Steps For More Accurate Results

- Why You Don’t Always Need to Check On Hand Stock

Place the pallet on a flat surface

Place the pallet on a flat surface at all times so that the product doesn’t fall over. You should really pay attention to this for the safety of your products and workers.

Mark the fork of the hand pallet truck

When moving double-deck pallets with a hand pallet truck, you can mark the maximum length of forks that can go in. This is done so that the wheel of the hand pallet truck won’t be on the skid pallet. If the wheel is on the skid pallet, the pallet will be damaged when you lift it.

Sort pallets in a neat way by type

If you use different kinds of pallets, put the empty ones in a neat stack according to what kind they are. This will make it easier to find the pallet when you need it, and you won’t use the wrong kind by accident.

Do not put more on a pallet than it can hold

Each pallet is made to hold a certain amount of weight. You have to do what this rule says. You can’t put more weight on a pallet than it can hold. If the load falls off the pallet, it will not only damage the pallet but also put your workers in danger.

Do not be exposed to direct sunlight for a long time

If plastic pallets are left in direct sunlight for a long time, they will become brittle and break easily. So, put your pallets somewhere where they won’t be in direct sunlight for a long time.

Pull on all three legs of the pallet

Even if you have to pull the pallet with a rope, tie the rope to all three legs of the pallet instead of just one to prevent damage.

Why plastic pallets are better than wooden ones

Plastic pallets are better than wooden pallets in a number of ways.

Let’s see.

Economical

In terms of cost, plastic pallets are better than wooden pallets because they last longer. Pallets made of plastic have a life span of between 5 and 15 years.

Yes, you will have to pay more up front than you would for wooden pallets. But the costs you pay back quickly in the long run.

Performance

When it comes to how well they work, plastic pallets have more consistent sizes than wooden pallets. It is also stronger and lasts longer because of how it is built.

The strength is also higher because a wooden pallet is made up of a single piece, while a wooden pallet is made up of several pieces that are put together.

Also, the surface of plastic pallets is better than that of wooden pallets because they don’t have nails or other rough spots.

Plastic pallets can also meet your needs if you use a conveyor or an automated system for moving things.

Sanitation

Plastic pallets can stand up to water. Does not absorb moisture. So you don’t have to worry about mold or bacteria growing on it. Plastic pallets are so strong that insects can’t even get through them. This means you don’t have to fumigate or heat treat them, which can save you time and money.

Safety

Since nails are not used to make plastic pallets, your workers will also be safer. Sharp objects can be made less likely to hurt people.

Aesthetics

In terms of looks, plastic pallets are better than wooden ones because you can change the color and make them look unique.

Environment

From the point of view of the environment, these plastic pallets can be reused. Pallets made of plastic can be broken down and made into other things.

You might also like:

- 5 Reasons Why It’s Important to Go to the Workplace in Person

- 4 Reasons Not to Work Too Diligently in Supply Chain Management

Types of plastic pallets

Based on their name, plastic pallets can be made in a number of different types and sizes. You have to decide based on what you need.

What are the different kinds of pallets?

In the next section, we talk about it.

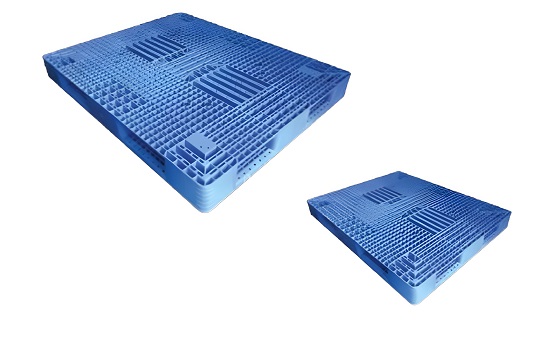

Reversible plastic pallet

This type of pallet, as the name suggests, can be used to store goods on both sides. Can be used both ways.

This type of pallet can’t be moved with a hand pallet truck because both the top and bottom are used to store things. Since the pallet is used to store things, there is no space for the wheels of the hand pallet truck to move the pallet.

But these pallets can be moved with a forklift. When it comes to moving it, this reversible plastics pallet has holes for forklift forks that can go in two ways or four ways.

There are also differences in how much weight they can hold, what materials they are made of, and how big they are. You can choose based on what you need.

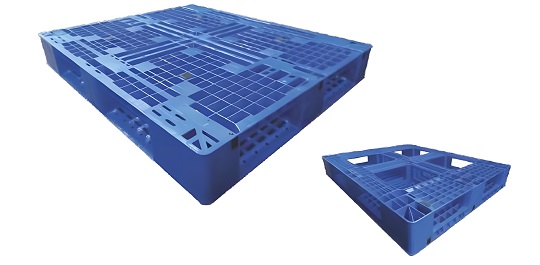

Double deck plastic pallet

The double deck plastics pallet can’t be used to store goods on both sides, unlike the reversible plastics pallet. Things can only be stored on the top side.

Items can be stacked on top of double-deck plastic pallets.

You can also get these pallets in different sizes, materials, and loads.

For the actual moving, you can use a forklift or a hand pallet truck that you can get to from all four sides.

Single deck plastic pallet

This kind of pallet isn’t meant to be put on top of other things. You can only put this pallet on the floor or on a storage rack.

Just like with the other two types of pallets, you can choose the size, material, and load capacity based on your needs.

For moving the pallet, you can use a forklift or a hand pallet truck, which you can get to from all four sides.

Conclusion

Pallets are often used to store goods or move them from one place to another. But that doesn’t mean you can use any kind of pallet without thinking about what you need.

Each kind of pallet is made from a different material and is a different size and shape to meet different needs. Your job is to figure out what you need so you can pick the right kind of pallet. Your choice will affect how well your business runs, how much space you have for storage, and even how safe your business is.

You can use some guides about the different kinds of pallets and how to use them to help you decide which one is best for you.

Hope it helps!

You should also send this article to your other friends so they can learn from it too. Join the scmguide telegram channel to learn more about how to manage the supply chain. You can use any of the articles on this blog for whatever you want, even if it’s for money. You don’t have to give credit.

by

by