In the world of manufacturing, every minute counts. Imagine downtime as a break in production—a moment that can greatly affect how productive and profitable your company is.

That’s why collecting and analyzing data about production downtime is incredibly crucial. It helps you understand how your manufacturing is performing and where you can make it better.

In this blog post, we’ll discuss why downtime data is important, how to collect it, the tools you can use, ways to understand it, the valuable insights it can provide, and how all of this helps strengthen your supply chain.

Before we go further into this topic, don’t forget to follow my LinkedIn account. You’ll get more helpful insights on supply chain management there.

Table of Contents

The Power of Production Downtime Data

Imagine being in charge of a busy manufacturing operation. Every choice you make affects how well your company does.

Now, think of downtime as a crucial moment when everything pauses. It might seem quick, but it really matters for your company’s success.

Downtime isn’t just a break—it disrupts how you work.

When machines stop, deadlines get pushed, and schedules go off track. This delay makes customers wait longer, and that’s not good for business.

But there’s good news: accurate downtime data can help.

It’s like a light showing how well your manufacturing works.

It’s not only about knowing when machines stop; it’s about understanding why.

Are some processes or machines causing more downtime? Is there a problem in your production line causing these pauses?

Imagine using a magnifying glass on your processes. With downtime data, you find hidden problems. You make smarter choices based on data, not guesses.

You can improve. You’re not guessing anymore; you’re finding where to focus. Maybe some machines need fixing before they cause more trouble. Or a process needs improving to avoid pauses.

Downtime data isn’t just numbers; it’s how you make your manufacturing better. It’s like a map guiding you past obstacles to a better way of working. It helps you choose wisely, making your manufacturing better.

So, when downtime comes, remember it’s more than a pause. It’s a chance to gather data, understand your work, and make it better. It’s your opportunity to steer your manufacturing to success, making every moment count for a brighter future.

Recording Production Downtime Made Simple

Imagine you’re like a conductor leading a musical performance, and every pause matters in your production line’s melody.

Now, think about recording downtime as capturing those pauses in the music.

This data isn’t just about pauses; it’s like a script that can help improve your manufacturing performance.

Here’s how you can do it smoothly.

Sort Downtime

Think of yourself as an explorer mapping new territories. Divide downtime into planned breaks and unexpected stops. But go deeper—think about why these pauses happen.

Is a machine causing trouble? Maybe it needs maintenance, or there’s a setup change causing a pause.

Breaking downtime into these smaller parts gives you the information you need to make precise improvements.

Choose Timing

Imagine you can travel through time in your production process. Decide how often you want to capture these pauses.

Should you record every pause as it happens, like a live broadcast? Or is it better to summarize hourly, daily, or by shift?

Real-time data is great, but you also need to be practical.

Find the balance between accuracy and what works for your operation.

Assign a Role

Picture yourself as a director casting actors in a play. Who’s responsible for writing down these pauses? Your skilled operators? Supervisors? Maybe a special team?

Assigning the job ensures your manufacturing story is accurate and complete.

Pick Tools

Imagine you’re in a tool shed, selecting the right tool for the job. You have choices. Traditional paper logs or whiteboards are visually clear.

But in the digital age, there are advanced options.

Specialized software can not only record pauses but also analyze and present them. Manufacturing Execution Systems (MES) act like high-tech conductors, coordinating collection and analysis seamlessly.

Following this plan means you’re not just collecting data; you’re getting insights.

You’re not only recording pauses; you’re composing a melody of improvement.

It’s like you’re using a magnifying glass on your production, uncovering hidden spots and making things better.

With these steps, you’re not just gathering downtime data; you’re shaping the future of your manufacturing success.

You might also like:

- Compete or Collaborate with Competitors? Which One is Better?

- How to Build a Reliable and Trustworthy Supply Chain Management Team: You Can Lead the Way!

Tools for Recording Downtime Data Made Simple

Imagine you’re building a toolkit like a skilled craftsperson. Each tool has a specific job, just like these methods for recording downtime data.

These methods are like your instruments for managing pauses in your production.

Let’s explore these options, each fitting a different pace of your work.

By Hand

Think of yourself as a history writer, noting down important moments in your manufacturing process.

The “Paper Logs” are like a diary where operators write down pauses on paper forms.

It’s a hands-on way to collect data, like putting together a puzzle.

Picture yourself as a visual communicator. Here comes “Whiteboards.”

It’s like a backstage plan displayed for everyone to see.

Passersby can know about production pauses, encouraging teamwork. It’s quick and simple to keep everyone informed.

Digital Solutions

Imagine you’re a data expert, effortlessly handling information.

“Spreadsheets” offer a digital canvas where you create your downtime picture. Whether it’s Excel or Google Sheets, these platforms help you organize, analyze, and see your data. It’s like a digital notebook you can easily edit and explore.

Now, think of yourself as a conductor. “Downtime Tracking Software” takes the spotlight. It’s not just about recording; it’s about understanding.

This software captures data in real time and turns it into meaningful insights.

With analysis and reporting features, it’s like having a whole data orchestra.

Imagine you’re into technology, excited about progress. Enter “IoT Sensors.”

These devices are like silent watchers, always looking for downtime. They automatically detect and record pauses, giving you a complete dataset. It’s like using tech to create insights.

Remember, each tool has its own tune. Whether you’re using pen and paper or the digital power of IoT, the goal is the same: to record your manufacturing journey. These tools aren’t just tools; they’re partners in making your work excellent.

Processing Raw Downtime Data Made Simple

Imagine you’re like a magical creator, turning basic materials into valuable insights.

When dealing with downtime data, you’re not just a collector; you’re like a conductor leading a symphony of information.

Here’s how you can turn this transformation into an artistic masterpiece.

Entering and Checking Data

Think of yourself as a careful organizer, making sure each data entry is perfect.

Accuracy is key.

Just like one wrong note can ruin a song, a mistake in data entry can affect your insights.

Check, validate, and ensure your data truly reflects reality. This careful checking makes sure your conclusions are based on solid facts.

Gathering and Analyzing

Picture yourself as a sculptor, shaping raw data into meaningful forms. Like collecting different musical notes to make a pleasing chord, you gather data into useful groups.

These groups are like the keys of a piano, waiting to be played.

Calculate how much time is lost, the average duration of pauses, and look for patterns.

It’s like finding the rhythm in your manufacturing process—some notes might be loud, some soft, but together, they tell a story.

Finding the Real Reasons

Imagine you’re a detective, uncovering the hidden truth.

Don’t just stay on the surface; dig deep into the reasons for downtime.

It’s like solving a musical problem by getting to the root cause, not just fixing what’s on the surface.

By understanding these reasons, you’re not only repairing what’s broken; you’re dealing with the main issues causing those pauses. It’s like practicing a tricky part of music until it’s perfect—you’re fine-tuning your manufacturing.

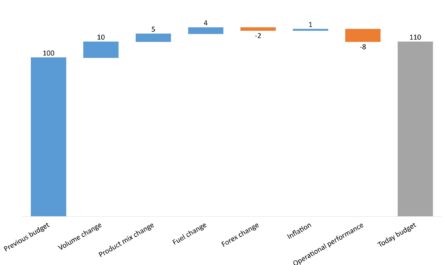

Making it Visual

Picture yourself as an artist, using colors and lines to make your data come alive.

Data alone can be confusing. But with visualization, you’re making it clear and understandable.

Think of graphs, charts, and dashboards as your canvas. They turn data into a visual masterpiece, showing patterns and insights. It’s like turning your data into a captivating piece of art that helps you make decisions.

Remember, as you process downtime data, you’re not just crunching numbers; you’re crafting a story.

Just like a composer arranges notes to create feelings, you’re arranging data to show insights.

At each step, you’re turning information into knowledge, and knowledge into action.

It’s not just about gathering data; it’s about leading an improvement journey, where every step brings a more harmonious manufacturing process.

You might also like:

- Unlocking Progress: The Power of Embracing Change

- Improving Your Bottom Line: Why You Can’t Overlook the Importance of Routine Performance Reviews

Deriving Insights from Downtime Data Simplified

Imagine you’re a detective investigating your manufacturing journey. The data you’ve gathered is like a treasure chest of useful information, waiting to be discovered.

As you dive into downtime data, you’re not just studying; you’re decoding a puzzle that can help your operation work better.

Here’s how you can use your skills to find important insights.

Find Problem Spots

Think of yourself as an explorer looking for hidden obstacles. By looking at downtime data, you can find where productivity is often slowed down.

This could be certain machines, processes, or shifts that always have more downtime.

Just like a ship avoids rough seas, your production needs to avoid these issues. Knowing them lets you focus on fixing what’s most important, making things smoother.

Improve Maintenance

Imagine you’re a conductor making sure all instruments sound good. Downtime data helps you see where things keep breaking down. It’s like finding a wrong note in music.

With this knowledge, you can plan maintenance better.

Instead of waiting for a breakdown, you can do maintenance to stop problems before they happen. This keeps your production in good shape and stops surprise downtime.

Make Things Better

Picture yourself as a craftsperson creating art. Your production process is like that. By looking at why downtime happens, you’re finding what’s not working well.

This is a chance to make things better. It’s like polishing a sculpture to make it perfect. Downtime data helps you make work smoother, improve processes, and have a better factory.

Compare and Improve

Imagine you’re a traveler comparing different paths to find the fastest one. Downtime data helps you compare how well things are going.

You can compare downtime between different times, shifts, or even parts of the factory. This shows you what’s good and what’s not. It’s like setting goals to make things better. This doesn’t just show where you are; it helps you keep getting better.

With each look at the data, you’re not just looking at numbers. You’re understanding how your factory works. You’re finding where things need fixing and making things run better. You’re making your factory work well, so it’s efficient and successful.

As you learn from downtime data, remember you’re not just studying; you’re changing how your factory works, step by step.

Using Downtime Data to Improve the Supply Chain Made Simple

Imagine you’re like a bridge builder, connecting your factory to the bigger supply chain world.

Downtime data isn’t just for your factory; it affects everything.

As you work with this data, you’re not just looking at numbers; you’re making a plan to make the supply chain work better.

Predicting Demand

Think of yourself as someone who predicts the weather. Downtime data helps you see when your production might slow down. Just like a weather person knows when storms are coming, you can know when production might have issues.

This helps you avoid making too many things when you might have downtime. When you know what’s coming, you don’t end up with too much stuff.

Working with Suppliers

Imagine you’re a conductor leading many groups. Suppliers work together, like musicians in an orchestra.

Sharing downtime data is like sharing your music sheets.

This helps suppliers understand when you’ll need things. They can match their deliveries with your production plans, so everything goes smoothly.

Making Things Faster

Picture yourself as someone who can speed up time. Downtime data helps you make things work better in the future.

By using this data to improve how you work, you’re not just stopping downtime; you’re also making things work faster.

It’s like making your supply chain music play faster. You can respond quickly to what people want, so you’re always ready.

Getting Better Together

Imagine you’re part of a team making music. Just like musicians work together, supply chain partners can work together too.

Looking at downtime data together helps everyone see problems. It’s like sharing music notes to make a song better.

By finding ways to improve together, the whole supply chain gets better.

Using downtime data for the supply chain isn’t just about fixing things; it’s about making things work better together.

You’re connecting production to the supply chain, so everything flows well.

Every time you use downtime data to make a plan, you’re making the supply chain better and more effective.

Concluding Thoughts in Simple Terms

As we come to the end of this journey, remember that you’re like the leader of a band for making your manufacturing better.

Collecting and using downtime data isn’t just a task—it’s a big change.

When you gather and study this data, you’re not just watching; you’re making things better, like directing a group of musicians to play well together.

Think of this data as a map for understanding manufacturing. It’s not just numbers; it’s a guide for making things smoother, finding problems, and making the supply chain work better. The things you learn are like musical notes that come together to make a great performance.

When you use the insights from downtime data, you’re not just making small improvements; you’re making a big difference. You’re creating a picture of better work, fewer problems, and being able to react to what people want. This is about going beyond goals; it’s about doing even better.

As you move forward with these insights, remember that each time you work without problems, you’re getting closer to success.

Using downtime data shows how much you care about doing things really well. With every choice based on these insights, you’re not just managing work; you’re showing how good you are at what you do.

Every bit of progress matters, and using downtime data helps you make each moment count.

I hope you find it helpful!

Please share this article with your colleagues so they can also benefit. For more insights on supply chain management, follow my LinkedIn account. You’re free to use all articles on this blog for any purpose, even for commercial use, without needing to give credit.

by

by