Table of Contents

Understanding the Real Cost of Ordering Too Much or Too Little

Imagine this. You’re managing inventory, and every time stock runs low, you place an order. Sometimes you buy in bulk, thinking you’ll save on costs. Other times, you order just enough to keep things moving. But somehow, your costs are never quite right. Either you’re stuck with excess stock collecting dust in the warehouse, or you’re dealing with stockouts that disrupt production and frustrate customers.

Sound familiar? This is the everyday struggle of inventory management. Too much inventory ties up cash and increases holding costs. Too little inventory leads to emergency orders, higher purchasing costs, and potential lost sales. Finding the balance feels like walking a tightrope. But what if there was a formula that could tell you exactly how much to order to minimize total costs? That’s where Economic Order Quantity (EOQ) comes in.

Before we go further into this topic, don’t forget to follow my LinkedIn account. You’ll get more helpful insights on supply chain management there.

The Formula That Takes the Guesswork Out of Ordering

EOQ isn’t just another theoretical concept; it’s a practical tool that can transform how you manage stock. The formula itself is simple:

Where:

- D = Annual demand (units per year)

- S = Ordering cost per order

- H = Holding cost per unit per year

At first glance, it looks like just another equation. But behind it is a powerful principle: order the right amount at the right time to minimize total inventory costs.

Here’s how it works. Every time you place an order, you incur an ordering cost. This includes administrative work, supplier coordination, and transportation fees. If you order too frequently, these costs add up quickly. But if you order in large quantities, you increase holding costs—the expenses of storing, insuring, and managing excess stock. EOQ helps you strike the perfect balance between these competing costs.

Why Ordering in Bulk Isn’t Always Cheaper

It’s tempting to think that bigger orders always mean bigger savings. Many suppliers offer discounts for bulk purchases, and on paper, that looks like a win. But have you ever considered the hidden costs?

Warehouses are not unlimited spaces. The more you stock, the more you pay for storage. Excess inventory also increases the risk of obsolescence, damage, or even theft. If you’re dealing with perishable goods, overordering can lead to spoilage and waste.

Then there’s the opportunity cost. Every dollar sitting in inventory is a dollar that could be used elsewhere—on product development, marketing, or scaling your business. EOQ helps prevent overstocking while still ensuring you have enough to meet demand.

Another factor to consider is demand variability. Some businesses face seasonal demand fluctuations, which means ordering in bulk might make sense in some months but lead to excess inventory in off-peak periods. By calculating EOQ, you create a flexible, cost-efficient ordering strategy that adapts to changes in demand.

You might also like:

- When Governments Make Trade Harder What Can Supply Chains Do?

- Why Your Supply Chain Will Never Be Perfect and That’s Okay

The High Cost of Stockouts and Last-Minute Orders

On the flip side, underordering can be just as costly. Have you ever had to place an emergency order because you ran out of stock? Express shipping costs are brutal. Not to mention the impact on your production schedule, customer relationships, and brand reputation.

When you don’t have enough inventory, operations slow down. If you’re a manufacturer, missing a key material can halt production altogether. If you’re a retailer, empty shelves mean lost sales. Worse, customers might switch to competitors who can fulfill their orders faster.

Beyond the immediate financial loss, frequent stockouts damage trust. Customers who experience repeated stock issues may start doubting your ability to meet their needs, which can push them toward competitors. EOQ minimizes this risk by helping you determine an optimal order quantity that prevents shortages without unnecessary overstocking.

Applying EOQ in the Real World

Let’s say you manage a company that sells industrial parts. You have a product with an annual demand of 10,000 units. Each time you place an order, you spend $50 on administrative and shipping costs. Storing each unit costs you $2 per year.

Using the EOQ formula:

This means the most cost-effective way to order this product is in batches of 707 units at a time. Any more, and you’re overpaying for storage. Any less, and you’re spending too much on ordering.

But what if your supplier offers a price break if you order 1,000 units at a time? Here’s where EOQ becomes a decision-making tool rather than a rigid rule. You need to weigh the discount against the increased holding costs and decide which option saves you more in the long run.

When EOQ Might Not Work Perfectly

While EOQ is a fantastic guideline, real-life inventory management is rarely this simple. Demand fluctuates. Supplier lead times can be unpredictable. Some products come with minimum order quantities. Others have volume discounts that make bulk purchasing more attractive despite higher holding costs.

In these cases, EOQ serves as a starting point rather than a strict rule. It helps you understand the baseline cost structure, so you can adjust based on market conditions, supplier agreements, or strategic inventory decisions.

For instance, if your suppliers offer significant discounts for larger orders, you might choose to order slightly more than your EOQ calculation suggests. Similarly, if you’re dealing with highly volatile demand, you might incorporate safety stock into your ordering process rather than relying solely on EOQ.

Another limitation of EOQ is that it assumes demand remains constant throughout the year. In reality, few businesses operate in such predictable environments. Combining EOQ with forecasting techniques can provide a more accurate and dynamic inventory management strategy.

You might also like:

- How Political Climate Shapes Manufacturing and Vendor Sourcing Decisions

- Feeling Overwhelmed by Supply Chain Chaos? Here’s How an Action Plan with Milestones Can Save You

Integrating EOQ into Your Inventory Strategy

To make EOQ work for you, it’s essential to track the right data. How much are you really paying for storage? How much does it cost you to place an order? And most importantly, how predictable is your demand? The more accurate your data, the more reliable your EOQ calculations will be.

Technology makes this easier. Modern inventory management systems can automate EOQ calculations, factor in fluctuating demand, and suggest optimal reorder points. If your company still relies on manual tracking, implementing EOQ can be a game-changer.

Additionally, EOQ can be combined with other inventory management techniques, such as Just-in-Time (JIT) and Safety Stock calculations, to create a more comprehensive strategy. For instance, companies with highly unpredictable demand might use EOQ as a baseline while maintaining buffer stock to handle sudden spikes in orders.

Case Study: EOQ in Action

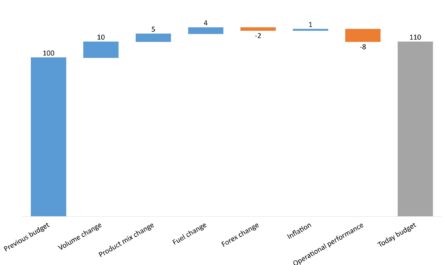

Let’s take a real-world example of a mid-sized electronics distributor. Before implementing EOQ, the company was placing inconsistent orders—sometimes every two weeks, sometimes once a month—leading to high storage costs and frequent stockouts.

By analyzing their order costs and storage costs, they calculated an EOQ of 850 units per order. This simple adjustment reduced their ordering frequency from 24 times a year to 12, cutting administrative costs in half. They also eliminated unnecessary storage expenses, improving cash flow.

The result? A 20% reduction in total inventory costs within six months, along with fewer instances of stock shortages. EOQ provided them with a structured approach to inventory that removed guesswork and improved efficiency.

The Bottom Line

Managing inventory without EOQ is like driving without a fuel gauge. You might get lucky and avoid running out of stock, or you might end up stranded with excess goods you can’t move. By using EOQ, you take control of your inventory costs, improve cash flow, and eliminate the stress of constant stock management.

Next time you’re about to place an order, stop and ask yourself—is this the most cost-effective quantity? If you’re not sure, EOQ is the tool that can give you the answer.

I hope you find it helpful!

Please share this article with your colleagues so they can also benefit. For more insights on supply chain management, follow my LinkedIn account. You’re free to use all articles on this blog for any purpose, even for commercial use, without needing to give credit.

by

by